GRIDCOOLER® Keel Cooler

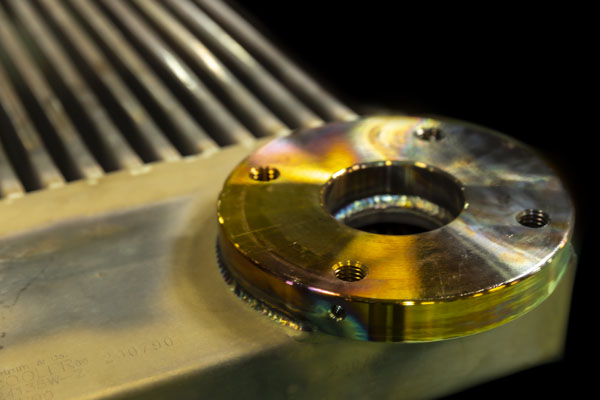

Featured One-piece Header Design

Fernstrum has continually evolved the GRIDCOOLER Keel Cooler’s design to improve efficiency and dependability. The rectangular one-piece header design has fewer joints for improved durability and provides greater flexibility in custom cooling solutions.

Material Options

Premium materials to help maximize your cooling system

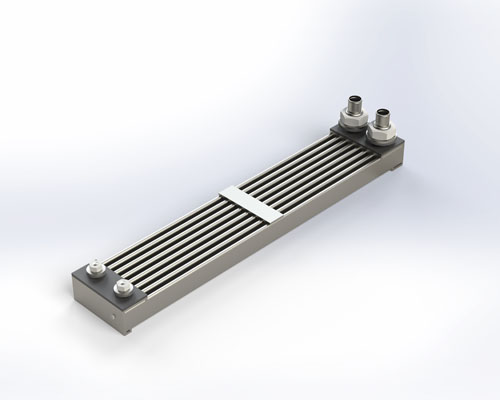

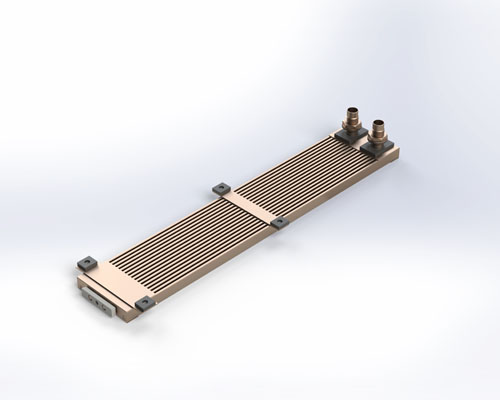

The GRIDCOOLER Keel Cooler is a completely assembled unit and is factory tested to ensure dependability. The rectangular shaped tubing used in its construction is structurally sound and provides a higher heat transfer rate than round tubing.

5000 Series Aluminum

The aluminum GRIDCOOLER Keel Cooler is designed specifically for unpainted aluminum hull applications in fresh or cold seawater environments. 5000 series aluminum alloy was selected based on its compatibility with unpainted aluminum hulls and saltwater corrosion resistance. The alloy compatibility between the hull and keel cooler prevents pitting and avoids potential damage from interacting metals. Aluminum units are tig welded for durability.

90/10 Copper-Nickel

The copper-nickel GRIDCOOLER Keel Cooler is crafted using heavy-walled rectangular 90/10 copper-nickel tubing. This alloy was selected based on its durability, heat exchange abilities, resistance to saltwater corrosion, and natural antifouling capabilities.

Contact our sales and engineering team for expert advice on cooler sizing, placement, installation, and service.

Applications

R.W. Fernstrum & Company is a trusted market leader in engineering and manufacturing custom cooling solutions for the marine industry. The GRIDCOOLER Keel Cooler has been successfully applied to cool all types of vessels in the commercial, government, and recreational markets worldwide.

Commercial, Government, and Recreational Applications

- ATB

- Barges

- Commercial Fishing Vessels

- Dredges

- Escort/Specialty Tugs

- Inland River Boats

- Buoys

- Drainage Systems

- Facilities’ Climate Control

- Heat Pump

- Hydroelectric Plants

- PSV

- Push Boats

- OSV

- Passenger Vessels & Ferries

- Patrol Boats

Stationary and Industrial Applications

- Buoys

- Drainage Systems

- Facilities’ Climate Control

- Heat Pump

- Hydroelectric Plants

- Industrial Process Cooling

- Irrigation Systems

- Lift Stations

- Offshore Wind Generators

- Onshore HVAC

- Pump Stations Engines

- Storm Sewer Systems

- Underwater Data Center

- Wave & Tidal Generators

Leading, not imitating.

Our commitment to quality means you get a reliable, long-lasting cooling system from the pioneer of the rectangular tube keel cooler. Since 1949, each marine heat exchanger is engineered to meet the requirements of your engine, vessel, and operating conditions.

The GRIDCOOLER Keel Cooler has continually evolved to meet the requirements of naval architects and the marine industry worldwide. Our team of craftsmen employ the latest technologies to enhance our manufacturing process. The result is a custom-designed GRIDCOOLER Keel Cooler that exceeds expectations.

Contact our sales and engineering team for expert advice on cooler sizing, placement, installation, and service.

Installation Options

Our expert engineers and sales team will help you determine the best installation solution. Please note the operating conditions and hull design of a vessel weigh heavily on how a unit is installed. Described below are a few common installations for a GRIDCOOLER Keel Cooler.

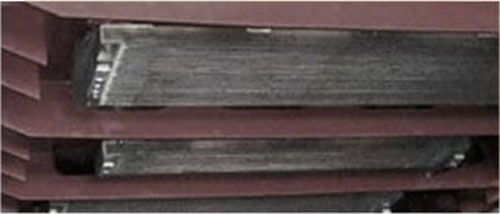

Recessed

Recessing a GRIDCOOLER Keel Cooler streamlines the installation and provides significant protection from potential damage. Independent tests conducted at the Vienna Model Test Basin have shown that drag is negligible when the unit is recessed into a ship’s hull. The position of the recess can be located on the side or bottom of the hull. This type of installation is common in new projects and ideal for fast-moving vessels.

External

An external installation typically applies fairing and side plates for added protection and to improve streamlining. This mounting option is commonly used in retro-fitting projects.

Side Mounted

Mounting the GRIDCOOLER Keel Cooler on the side of the hull prevents potential damage to the unit. It is ideal for situations where a keel cooler cannot be mounted to the bottom of the hull. Note: When recessing the unit into the side of the hull for generator sets and/or equipment operating at dockside, angle the top of the recess box to allow convection current over the cooler.