How Keel Cooling Works

A keel cooler is a closed circuit cooling system mounted externally on the vessel’s hull below the waterline. The concept of keel cooling is similar to the application of a radiator on a car. Engine coolant is circulated through the keel cooler, which transfers heat from the coolant before it returns to the engine. The keel cooler is in constant contact with seawater allowing the cooling system to efficiently transfer heat between the coolant and seawater.

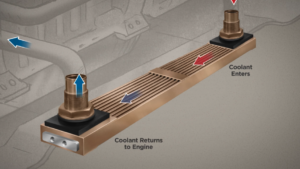

The GRIDCOOLER® Keel Cooler is mounted externally on the hull below the waterline. The engine coolant is circulated through the GRIDCOOLER Keel Cooler, which transfers heat from the coolant before it returns to the engine. The keel cooler is in constant contact with seawater to efficiently transfer heat.

The GRIDCOOLER® Keel Cooler is mounted externally on the hull below the waterline. The engine coolant is circulated through the GRIDCOOLER Keel Cooler, which transfers heat from the coolant before it returns to the engine. The keel cooler is in constant contact with seawater to efficiently transfer heat.

Advantages

Compared to an open circuit cooling system (inboard heat exchanger), a closed circuit cooling system provides several distinct advantages. A closed circuit cooling system eliminates the need for an inboard heat exchanger, raw water pumps, strainers, seawater piping, and the high maintenance associated with open circuit cooling systems. It also eliminates silt and sand buildup in the cooling circuit and protects the system from salt water corrosion. The use of a keel cooler eliminates the need for seawater to enter the hull. From an environmentally friendly perspective, keel cooling provides a zero discharge solution eliminating the possibility of contaminants entering the seawater.

Keel Cooling Helps Eliminate:

- High Maintenance

- Raw Water Pumps

- Sand & Silt Buildup

- Seacock

- Seawater Circuit

- Seawater Piping

- Strainers